Our Product

Expertise across disciplines and dedication to sustainable material development

As a professional monofilament producer, Ri-Thai International Inc. focuses on the production of monofilaments. Since our establishment in 1977, we stand firm on our founding purpose and continue to focus on the research and development and innovation of products that enable us to respond to the diverse needs of customers.

In 1977, we establish our first production line in Taiwan to produce PET monofilaments used for making Zipper fasteners. Three years later, in 1980, we became the first ever Taiwanese producer to develop Nylon monofilaments used for producing hook and loop fasteners. So far, our production plant in Taiwan has more than 30 sets of production lines that can produce a wide range of products. In addition to the general round monofilaments, we also produce monofilaments of many other different structures, such as: profiled cross-section, hollow monofilament, bi-component monofilament, etc. They can be matched with a variety of materials, color masterbatches, and additives to meet the customers’ requirements for specific color, function, diameter / size, physical properties, etc. Our plant is equipped with a variety of spools that meet the processing needs of most customers and can produce diversified products that satisfy demands from different industries.

During the process of manufacturing monofilaments, we keep the essence of material as they are, without adding other ingredients. If the color and physical properties specified by the customer require the addition of color masterbatches and additives, we will use additives provided by reputable suppliers to ensure that the products comply with REACH, RoHS, and other international material safety regulations. Being socially and environmentally responsible, we also obtain Oeko-Tex certification for our products so that they are tested to avoid any potential impact on human health, and also to be responsible for the greater community, as well as ensuring that the additives will be eco-friendly.

With the promotion of the United Nations since the declaration of the United Nations Conference on the Human Environment in 1972, countries have tried to reduce the emission of carbon dioxide and harmful gases that damage the ozone layer through international cooperation and international treaties in order to prevent global warming from becoming worse. Ri-Thai International Inc. has developed the use of recycled materials for eco-friendly monofilament production and obtained the Global Recycle Standard (GRS) certification as our contribution to better environmental sustainability.

Structure | Material | Dia./Size | Color | Physical Properties | Function | Spool | Downstream Process |

Round & Profiled cross-sections | Petro-based (PET, PBT, TPEE, PA6, PA66...) | Min. 0.08mm | Raw | Breaking Strength | Abrasion Resistant | Approx. 1kgs-14kgs | Circular knitting Flat knitting Warp knitting Weaving |

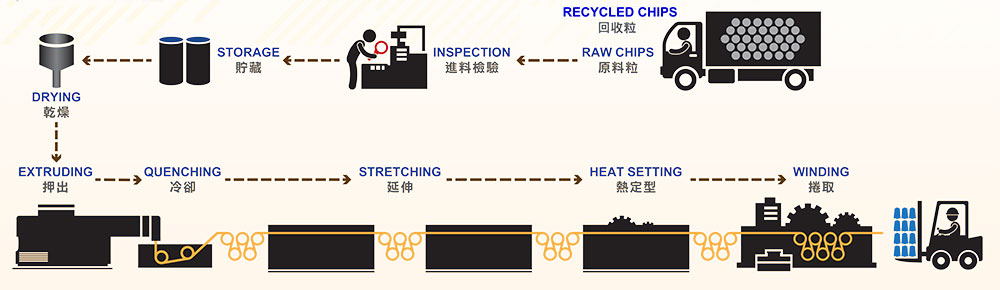

MANUFACTURING FLOW DIAGRAM OF MONOFILAMENT YARN

RECYCLED CHIPS/RAW CHIPS → INSPECTION → STORAGE → DRYING → EXTRUDING → QUENCHING → STRETCHING → HEAT SETTING → WINDING