Bi-component Monofilament Yarn

- It is composed of two polymers with different chemical and/or physical properties

- It is extruded from the same spinneret with both polymers within the same filament.

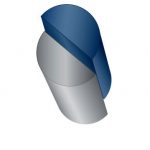

Cross-sections

- Sheath/Core

- Adhesion: The outer layer of the sheath-core monofilament is made of a low melting-point polymer while the core is made of a high melting-point polymer. The fabric can be fused after the thermo-fixing process, resulting in a mesh with better physical properties compared with fusible yarn. Melting the outer layer of the sheath-core monofilament makes the material resistant to water and wind while maintaining breathability.

- Features: Additives can be applied to the outer layer of the sheath-core monofilament to make it abrasion-resistant, flame-retardant, weather-resistant, antibacterial, antiviral, odorless, etc. Other materials can also be leveraged to achieve the desired monofilament yarn properties while optimizing costs.

- Protection: Monofilament yarns dyed with fragile additives such as fluorescent or luminous masterbatches can be strengthened by having the outer layer of the sheath-core monofilament act as a barrier that improves color fastness against washing, friction, and more.

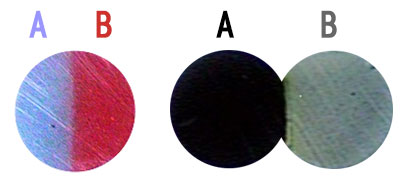

- Side-by-Side

Cross section of monofilament

- Dual Color: Mixing the color of Side A and Side B, creating a bichrome effect.

Advantages

Thermo-fixing for fusion bonding

- Directly bond the mesh by thermo-fixing.

- Available for different combinations with different bonding temperatures

- The bonding produces a smooth and beautiful mesh and uniform distribution of adhesive.

Special functionality

- Combining bi-components with specific functional additives will provide a multiplied effect

Diversity

- Customization and different bi-component combinations of offerings

Cost Reduction

- Applying the expensive material to merely one of the layers, which could reduce the overall cost and highlight its effect

- Fabric does not require secondary coating process

Stable physical properties

- Place materials with desired physical properties in the core layer to maintain the overall physical properties of the monofilament yarn

Eco-friendly

- Thermal bonded webs, meshes, fabrics allows the monofilament yarn to be self-bonded without adding chemicals. This reduces the use of chemicals, consumes less energy, and generate less pollution and carbon footprint

- Circularity: Bi-component monofilament yarn are usually co-extruded with materials similar to the plastic family, making recycling hassle-free

Unique product features

- Through the use of high-performance materials/additives, we provide more diversified product features, such as fluorescence, luminous , thermochromic, deodorization, etc.

- Put the color masterbatches or additives in the inner layer of the bi-component monofilament yarn to protect the more fragile materials from damages caused by UV radiation or temperature and help maintain color fastness and reduce color migration

Specifications

Combination | Diameter | Denier | Recommended | Core Ratio |

PE/PP | 0.15~0.30mm | 145d~600d/f | 130℃ | 10 to 90% |

TPEE/TPEE | 0.10~0.50mm | 90d~2,210d/f | 150℃ | |

TPEE/PET | 90d~2,415d/f | 150℃ & 180℃ | ||

LM PET/PBT | 0.12~0.20mm | 110d~365d/f | 115℃ |

Applications

It is not limited to the following applications. If you have any idea, we are willing to study.

Car Interior

Home Textile

Apparel/Shoes/Bags/Accessory

Insulation sleeves

Office Furniture

And More...