FAQ - Monofilament yarn

An Overview of Monofilament Yarn

01. Question

What is monofilament yarn?

Monofilament yarn is a single plastic solid thread. Its cross-section is solid and usually circular, though the shape can be altered to be flat or triangular. The cross-section can also be made of two polymers structured side-by-side or sheath/core. Generally, the monofilament is wound on individual spools like shown in the below image. We offer different spool types in terms of size, shape, and material (paper, single or double flanged plastic) to address different client needs.

Learn more about Ri-Thai’s products package

02. Question

How is monofilament yarn produced?

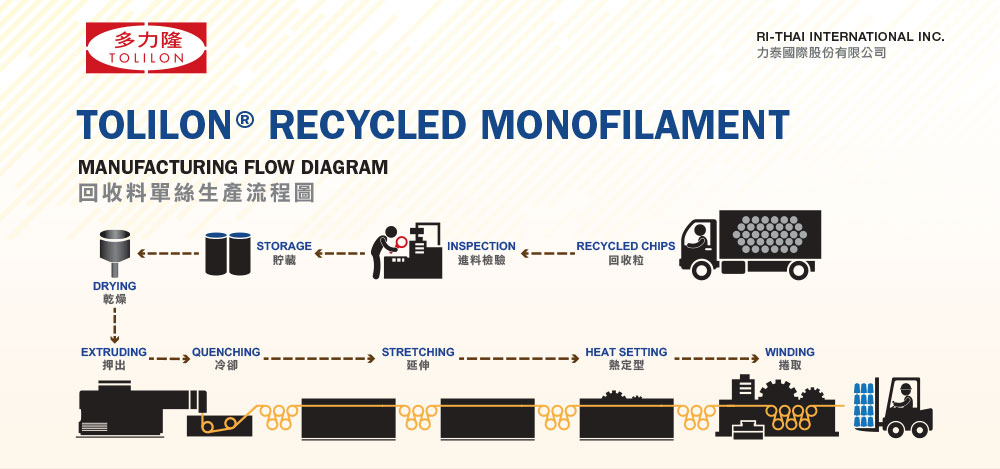

Monofilaments can be quenched in air chambers (air quenching) for the production of yarns with smaller diameters, or they can be quenched in a water bath (water quenching) for the production of yarns with larger diameters. Ri-Thai’s monofilaments are produced via water quenching, showcased in the below diagram. First, the melted chips are extruded through a spinneret containing one or more holes. Then the monofilament is quenched in water, stretched, and finally heated to ensure its robust physical properties. Lastly, the monofilament yarn is wound on individual spools.

03. Question

What is meant by the monofilament yarn’s physical property?

The monofilament yarn’s properties refer to the monofilament yarn’s physical properties, which include the size (diameter, denier, decitex), breaking strength, tenacity, elongation at break, and shrinkage.

The breaking strength and tenacity refer to the maximum amount of stress that the monofilament yarn can withstand until broken; elongation at break, or elongation, refers to the monofilament yarn’s percentage increase in length compared to its original length before breaking; shrinkage refers to the monofilament yarn’s percentage decrease in length compared to its original length after heating, which also includes boiling water shrinkage and heat shrinkage.

Furthermore, per the quality requirements from downstream product uses, on top of the monofilament yarn’s physical properties, the monofilament yarn may also need to possess qualities such as being fire resistant, weather resistant, heat resistant, abrasion resistant, hydrolysis resistant, and more.

04. Question

What ranges of yarn diameters, in denier (D), can be produced via air quenching and water quenching?

The air quenching method can produce yarns with a diameter of 20D-50D or smaller. The water quenching method can produce yarns with a diameter of 60D or larger. Because Ri-Thai uses the water quenching method, our monofilament yarn covers a diameter range of 50D-60D and larger (>0.08mm).

Please refer to the below table for more details.

05. Question

Where can we find monofilament yarn in everyday life?

Some examples include but do not limit to hook-and-loop fasteners (hook strip), tennis strings, fishing lines, zippers (teeth), filters in household appliances like the air conditioner, the treadmill walking belt, tire cords, protection sleeves, the mattress (spacer fabric), and shoe components.

06. Question

What are some downstream processing examples for monofilament yarns?

The list includes but does not limit to weaving, flat knitting, circular knitting, warp knitting, and braiding.

07. Question

How does monofilament yarn reduce environmental impact?

Its larger diameter makes it inherently durable and less prone to shedding microfibers.

All colors are solution-dyed, saving energy and reducing water pollution during the manufacturing process compared with traditional dyeing methods.

Read about Ri-Thai’s solution-dyed offer

The monofilament yarn can be produced using recycled and more sustainable materials such as rPET, bio- PET, or PLA per the client’s request.

Get in touch to see samples

Leveraging advantages of our bi-component monofilament yarns, the fabrics (or textiles) will be able to be combined seamlessly in the heat setting process to achieve thermal-bonding, meaning chemical bonding is left out, lowering energy consumption and environmental pollution.

Read about Ri-Thai’s bi-component monofilament yarn