Ri-Thai Recycled PET Monofilament Yarn

Keeping plastics from going to landfill and the ocean

The Process of Recycled PET filament Yarn

Currently, recycled PET filament yarns are mainly made with recycled waste plastic bottles. The production of these filament yarns requires a high level of cleanliness to avoid impurities in the spinning process, such impurities could affect the efficiency and the quality of filament yarns. For this reason, the journey from recycling waste plastic bottles to clean filament yarns is not an easy nor a short path to take.

Waste plastic bottles are recycled, washed, and sorted according to colors and levels of cleanliness. They are compressed into bales by machines. The bales are de-labeled, sorted, crushed, washed, removed of impurities, dehydrated, and processed into clean PET flakes, which are pelletized through the processing plant to become recycled PET chips, which will be sent to the filament yarns factory for high-temperature melt spinning, and finally, be used to make recycled PET filament yarns.

GHG Emissions

Environmental Impact of Products

RAW MATERIALS SOURCE | USED PROCESS | GHG EMISSIONS |

PET | Fossil Fuel Based | 2.83 |

Recycled PET Flake | 1.03 |

The Pros and Cons of Recycled PET

Pros

Keeping plastics from going to landfill and the ocean

Reduced needs for mining oil and gas from our planet to further reduce carbon footprints

Cons

Recycling has its limitations

Difficult to ensure color consistency

Ri-Thai Recycled PET Monofilament Yarn

Through the following presentation, we would like to invite you to learn a little more about the global sustainable movements and our recycled PET (rPET) Monofilament Yarn at Ri-Thai.

Highest Standards for the Best Product

We use rPET chips from Far Eastern New Century, the largest producer of rPET in Asia, and other major chip suppliers in Taiwan.

Our products meet the OEKO-TEX Standard 100, the highest standard for harmful RSL.

The GRS (Global Recycled Standard) standard applies to products that contain 20% or more recycled content.

At Ri-Thai, we believe 100% recycled content is the future for the market.

Ri-Thai is GRS certified 90%-100% post-consumer recycled polyester monofilament yarn

Virgin PET vs. Recycled PET

Physical Properties | Diameter | Heat Aging | Dyeability | |

Virgin PET | Similar | Similar | Similar | Similar |

rPET Mono. |

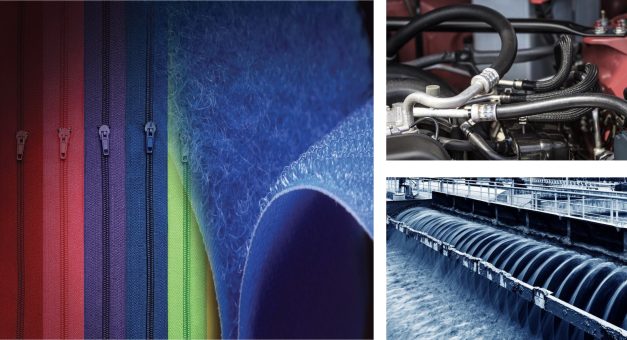

Applications

Zipper Fastener

Hook & Loop Fastener

Filtration Fabric

Insulation Sleeves

Conveyor Belt

Home Textile

Apparel

Footwear