Solution-dyed Monofilament

- Reduce water pollution. Environmentally and

Socially Responsible

Process

- Reduction in energy usage

- Efficient and Responsible Supply Chain

- Superior Color Fastness

- Unlimited Color Customization

Our Commitment to Sustainability

At Ri-Thai we pride ourselves in spearheading the new frontier of innovation in monofilament yarn, in line with our commitment to sustainability and the global circular economy. With 40 years of experience in the production of colored monofilaments, we are constantly improving our process efficiency and masterbatch selection by working with international partners that are equally experienced in their fields, such as Avient, formerly known as Clariant.

Ri-Thai is historically known for supplying colored monofilaments to produce hats and artificial-turf fields, most notably for the Texas Stadium, formerly known as the Texas Cowboys’ home in the 1990s. In recent years, the company has gained recognition in outstanding management of color customization, and color calibration and stability, becoming an entrusted partner of globally renowned tech giants and sports brands.

Furthermore, to ensure our products and production operations adhere to the highest of industry standards, Ri-Thai is certified in UKAS-accredited ISO 9001:2015, Standard 100 by OEKO-TEX®, and the Global Recycled Standard (GRS) with 90-100% verified recycled content.

What is Solution-Dyed Technology (Dope Dyed or Waterless dyed)

For most organic and inorganic fibers, the batch-dyeing process takes place in the last stages, which often yields negative environmental and social impacts. Experienced in solution-dyed technology, Ri-Thai reverses this process by first mixing the pigment with base resin to create a color masterbatch before the monofilament yarn is made. At Ri-Thai, sample batches are tested before other base resins are mixed in for mass production to ensure top quality. It is also worth noting that solution-dyed technology can be used in the production of a wide range of fiber products and not just monofilaments, outpacing traditional production methods.

NOTE: the images used are for illustration purposes only and may not be accurate in color.

The Advantages of Ri-Thai’s Solution-Dyed Monofilaments

By changing the production process and the nature of the fiber (monofilament yarn) itself, several advantages can be reaped, not limited to the below.

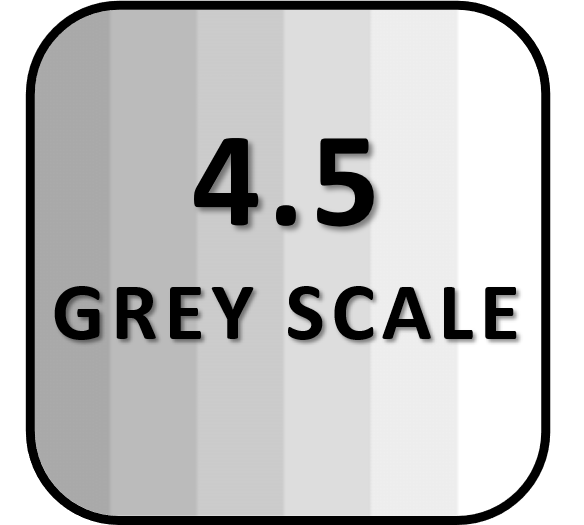

Superior Color Fastness

Since the pigment is integrated homogeneously into the monofilament yarn, the color is not only more vibrant but also provides excellent color fastness against washing, friction, UV, and heat exposure, achieving a 4-4.5 grade on the Grey Scale test.

Unlimited Color Customization

We have partnered with Avient for 40 years, one of the top international masterbatch color providers. Together, Ri-Thai and Avient have perfected the production process by following the highest of operation standards and improved the formula to speed up the mixing process without compromising color stability between batches or inducing color bleeding. Prior to mass production, Ri-Thai additionally conducts a spectrometer test to ensure color accuracy.

Any desired color selection can be made available, including the most challenging, bright, and fluorescent colors. As an added value, Ri-Thai can provide monofilaments with a sheath-core structure to further strengthen the bright and fluorescent monofilaments.

Environmentally and Socially Responsible Process

It is thanks to Ri-Thai’s commitment to consumer protection and operating to the highest of standards that enabled the company to obtain its OEKO-TEX® certification. This means Environmental Quality experts are present to ensure no harmful chemical substances or heavy metals are used during the entire process, keeping both the workers and the environment safe.

Water

One of the biggest advantages of switching to solution-dyed monofilaments is the significant reduction in water usage and chemical agents throughout the production process. Hence, reducing COD and water footprint.

Efficient and Responsible Supply Chain

Our raw materials are provided by a roster of partners that are equally committed to sustainability. Additionally, our partner suppliers and Ri-Thai’s production operations are localized in Taiwan, Mainland China, and Vietnam, reducing our overall CO2 footprint significantly. This also enables efficient adjustments to the local markets’ needs and a faster delivery time for customers.

Carbon Tax

Using certified eco-friendly materials decreases overall input costs and energy consumption compared with traditionally dyed materials, helping clients reduce their carbon tax depending on the country they are based in. Please consult with local environmental authorities for more information.

Endless Applications and Possibilities

The nature of the technology enables the production of monofilaments in any color that can be used for most industrial and commercial purposes, giving clients endless product development opportunities. Ri-Thai has been a trusted partner by the most beloved brands worldwide thanks to the company’s expertise and ability to swiftly resolve concerns posed by the clients.

Read More about the different applications by clicking on each image.