FAQ - PET material

01. Question

What is PET resin?

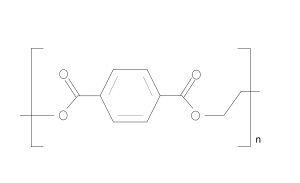

PET stands for Polyethylene Terephthalate. It is a thermoplastic (see note) invented in the 1940s. It is produced by the polymerization of Ethylene Glycol (EG) and Purified Terephthalic Acid (PTA), which can be extruded into fibers or molded into food and beverage containers and bottles.

(Note) Thermoplastics are plastics that react to temperature changes by softening when heated and hardening when cooled.

02. Question

What are PET’s characteristics?

High tenacity and robust mechanical properties

High rigidity and hardness

Very low moisture absorption

Good chemical resistance to acids

High transparency and gloss

03. Question

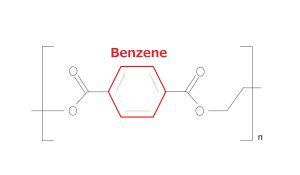

Why is PET rigid?

PET’s molecular structure contains a Benzene ring (Benzene, C6H6), which is what gives this polymer its rigid characteristic.

04. Question

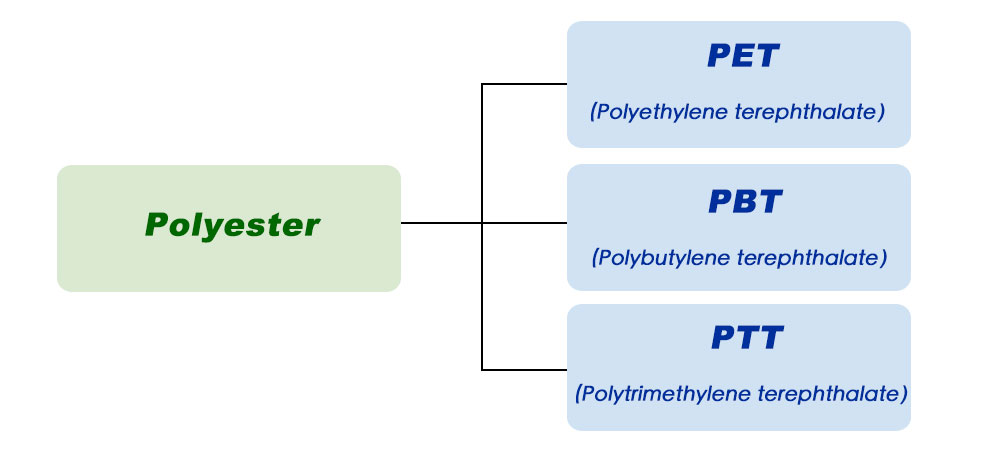

Is Polyester the same thing as PET?

Polyester is an umbrella term for synthetic materials that include PET. In the context of fiber and textile applications, PET (Polyethylene Terephthalate) is often referred to as “Polyester”.

05. Question

Can PET be recycled and reused?

Yes. Recycled PET is currently made of PET bottles and other types of containers that are collected, cleaned, and then recycled mechanically. In addition to being recycled into packaging materials, recycled PET is also upcycled in the manufacturing of yarns, including monofilament yarn and multifilament yarn, both widely used in clothing, home textiles, shoes, and more to achieve circularity.

06. Question

What are some application examples for PET?